The use of fiberglass reinforced polyester has extraordinary characteristics and countless application possibilities.

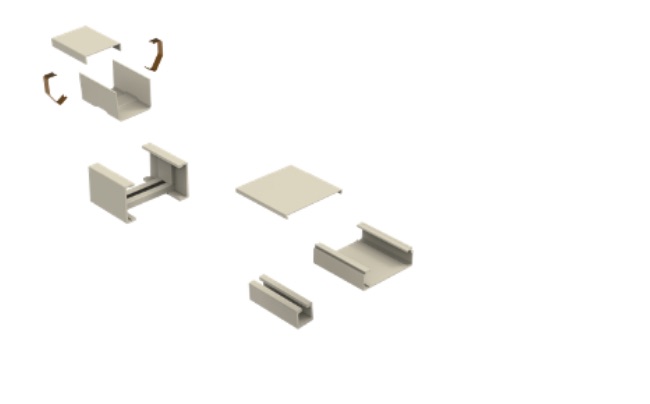

EBO SYSTEMS produce both pressed and pultruded fiberglass items: cable trays, ladders and ground ducts, support systems, standard handrails and on specific request. Each series is complete with covers, accessories and connection systems.