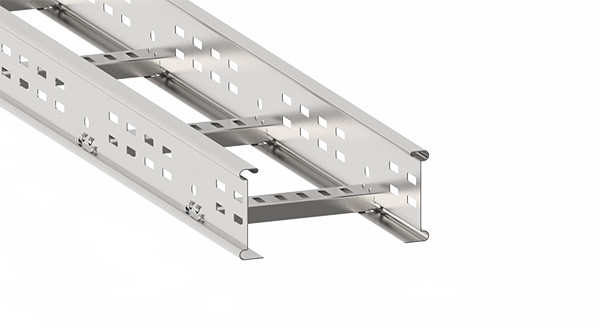

Maximum ventilation and simplicity of derivation and inspection of cables

The ladder tray typology assures the maximum ventilation of the power cables, so allowing their optimal electrical conduction and the natural exit of undesired extraneous bodies.

The addition or replacement of cables can be easily made without having to make modifications of installation, as every point of the route can be used as entrance/exit. Even the inspection of cables is easy.

Easiness of cable fastening

The wide range of available rungs allows unlimited options for fixing cables and service anchorages, by using commercial cable ties, band clamps or U-bolts.

High mechanical resistance and load capacity

The sections of side profiles and rungs, available in a wide thickness range, have been designed in order to guarantee high load capacities even with large distances between supports. The correct coupling by means of bolted splice plates, guarantees the mechanical continuity, becoming a point of strength.

Certified weldings

In all the welded ladder tray straight elements, the weldings are robotized and controlled by qualified personnel at the IIS (Welding Italian Institute), which has certified our welding procedures EN ISO 15609-1. Our operators periodically attend updating courses concerning the latest techniques.

Innovative clinched system

The HP 2.22A series, ladder tray with clinched rungs (without welding), allows the production in Sendzimir galvanized steel and in stainless steel without a chemical passivation treatment, with a considerable financial saving. Its torsional stiffness is higher than the bolted or riveted versions

Freedom of composition

The ladder trays with bolted rungs can be supplied preassembled or to be assembled, allowing the maximum freedom of installation and minimizing both the volumes and the transport costs.

Compliance with regulations

The system is manufactured in conformity with the IEC 61537 European norm and with the American (Canadian) NEMA VE 1 (CSA C22.2 No. 126.1), all of international value. It has the CE and IMQ marking. Fire resistance certifications, or certifications for installation in seismic environments or specific certifications required by the customer are also available.